At CASTLEY, it is more than just manufacturing parts; it is about shaping possibilities. Being a leading company in the field of precision manufacturing, CASTLEY has translated its love for craftsmanship and commitment to quality into artistic levels of customization and processing of CNC parts.

Our professional team with inexhaustible enthusiasm and consummate skills devoted to every project as an embodiment of aspiration for perfection. We can convert your dreams into reality using our micron-precise technology on a range of materials including strong aluminium alloys, durable stainless steel; conductive copper or flexible plastics.

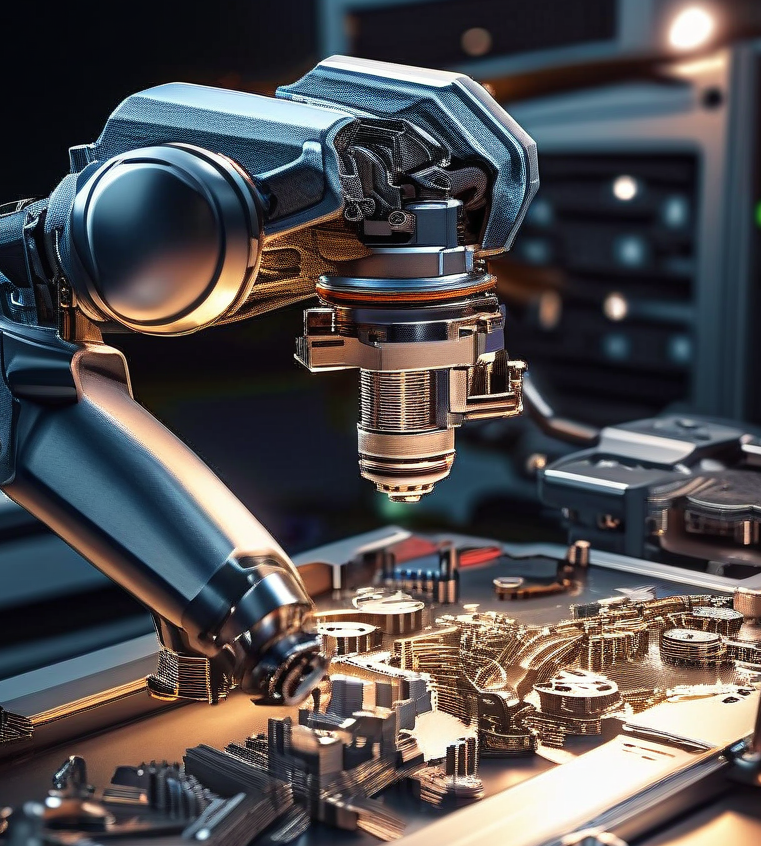

The processing process of CNC parts usually includes multiple links such as design, programming, processing and inspection. In the design stage, engineers need to design a reasonable part structure based on the product's needs and usage environment. In the programming stage, technicians convert the design plan into a code that can be recognized by the machine tool to ensure the smooth progress of the machining process.

In the processing stage, the machine tool performs precise cutting and processing according to the preset program. Finally, in the testing stage, professional testing equipment and means are used to conduct comprehensive quality testing on CNC parts to ensure that they meet the design requirements.

CNC machining parts, that is, computer numerical control machining parts, are an indispensable part of modern manufacturing. With their high-precision and high-efficiency processing characteristics, they are widely used in various fields such as automobiles, aviation, and electronics. In the machining process of CNC parts, computer programming controls the movement of the machine tool to achieve precise manufacturing of complex shapes.

Whether it is a delicate gear or a complex mechanical structure, CNC technology can complete the transformation from design to physical object with its excellent stability and reliability. With the advancement of science and technology, CNC processing technology is also constantly innovating, injecting strong impetus into the development of modern industry.

The quality and precision of CNC parts directly determine the performance and reliability of the final product. In the CNC machining process, every step is strictly controlled, from the selection of materials to the setting of processing parameters, to the final inspection and calibration, all striving to achieve the best state.

At the same time, CNC machining is also highly flexible and can easily cope with processing needs of different shapes and sizes. This makes CNC parts the first choice for manufacturing many high-precision products, providing strong support for modern industrial production.

CNC parts have a wide range of applications. In the field of automobile manufacturing, CNC parts are widely used in the manufacturing of key components such as engines and chassis, improving the performance and safety of automobiles. In the aviation field, CNC parts provide stable and reliable mechanical structures for aircraft with their high precision and high reliability.

In addition, CNC parts also play an indispensable role in fields such as electronics and medical equipment. With the development of intelligent manufacturing, CNC parts will show their unique advantages and value in more fields.

We produce directly with custom made CNC machining service being our specialization.

Our major products are Bicycle parts, Aluminum switch panel,camera case,scooter rims,optical fiber machine components,etc.

The main machines we have are CNC machining center,CNC lathe machines and normal milling machines,lathe machines,grinding machines and wire cutting machines.

In addition to this, we have completed testing equipment consisting of CMM,Two coodinate measuring machine, height gauge,hardness gauge etc.

Our team includes talented engineering team, technical team, quality management group and sales force.

We have been granted ISO9001 quality management system certification for effective delivery of products and services that meet customers’ expectations both locally and abroad making us a reliable supplier of CNC machining.

High precision, rapid production, customizable designs, suitable for various industries, enhancing production efficiency and quality.

Efficient mass production, precise details, durable and cost-effective, suitable for complex shapes and sizes.

Rapid prototyping, no tooling required, capable of printing complex geometric shapes, wide material selection, endless innovation possibilities.

Precision cutting and forming, high-quality metal parts, customized services, widely used in construction and manufacturing.

CASTLEY provides customized CNC parts services in a variety of materials, including but not limited to aluminum alloy, stainless steel, copper and plastic, etc. We select suitable materials for processing according to the specific needs of our customers.

Absolutely. CASTLEY has advanced CAD/CAM systems and experienced technical personnel, capable of handling part design and manufacturing tasks of various levels of complexity.

We use precision CNC machine tools and strict quality control processes in the customization process. From design to final product inspection, every step is carefully inspected to ensure product quality and accuracy.

Yes. CASTLEY not only provides single-piece customization services, but also has the capability of mass production. We have efficient production processes and flexible resource allocation to ensure that even large-scale orders can be completed on time.

Our customer service team is ready to answer any questions you may have and resolve any issues that may arise. We consider customer satisfaction as our top priority and are committed to providing timely support and solutions.