Custom Sheet Metal Fabrication Services

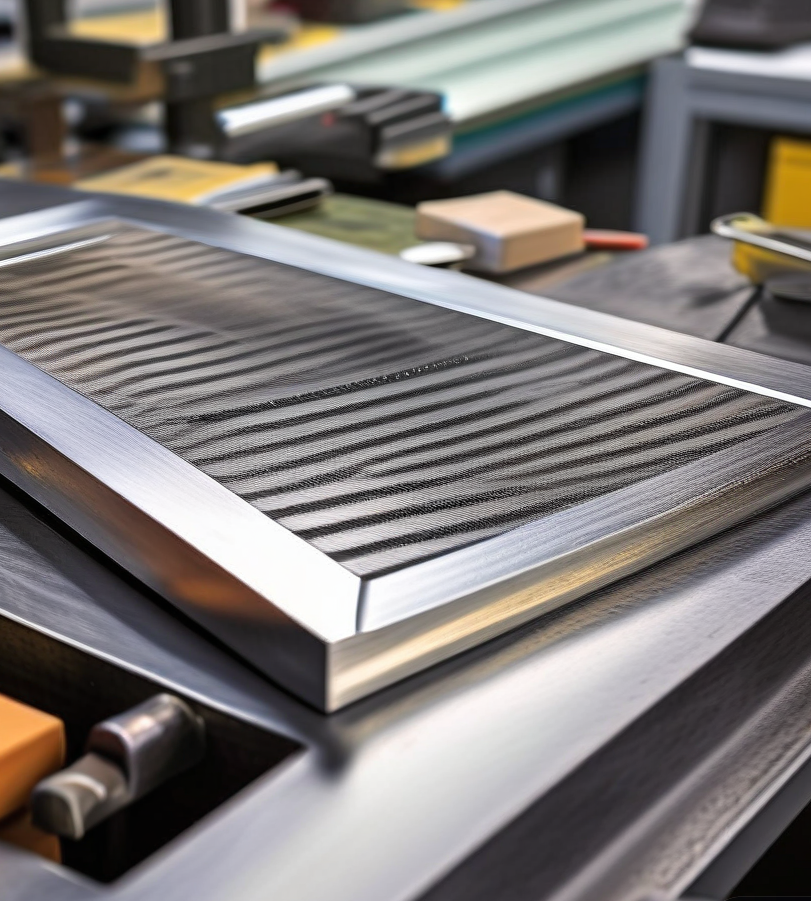

Our custom sheet metal fabrication services provide unparalleled design versatility and machining precision to a variety of industries. Whether it's aerospace, automotive, electronics or any other field that requires precision metal parts, we have the capabilities to meet your requirements.

We have full-process solutions from concept design to final product delivery, and cutting-edge CAD/CAM technology helps us transform our customers' design concepts into actual manufacturing blueprints. Our team consists of experienced designers, engineers and technical experts who are proficient in various metal processing techniques and ensure that each product meets strict quality standards.

At the same time, we also have a variety of materials to choose from that can meet the specific requirements of each project, including different grades of stainless steel; aluminum alloys, brass, copper and other alloys, etc. We understand the relevant performance characteristics of each material and will advise you on the best options for your project accordingly.

In the field of sheet metal processing, material selection is equally critical. Different metal materials have different physical and chemical properties and are suitable for different processing methods and application scenarios. Therefore, it is very necessary for sheet metal processing companies to be familiar with the performance characteristics and application range of various metal materials.

At the same time, with the increasing awareness of environmental protection, choosing environmentally friendly and recyclable metal materials has become an important trend in the industry. This can not only reduce environmental pollution during the production process, but also improve the market competitiveness of the product.

In addition to material selection, surface treatment during sheet metal processing is also an important link. Through spraying, electroplating and other methods, the corrosion resistance, aesthetics and functionality of the metal surface can be improved, and the added value of the product can be increased.

In the field of industrial production, sheet metal fabrication plays a vital role. This is a process in which metal sheets are processed into specific shapes and structures through a series of processes such as shearing, stamping, bending, and welding. From simple metal brackets to complex electronic product casings, sheet metal processing has a wide range of applications, covering almost every corner of modern industry.

In sheet metal processing, precision and efficiency are key. Modern processing equipment, such as CNC machine tools and laser cutting machines, allow processing accuracy to reach unprecedented heights. At the same time, automated production lines and advanced process management have greatly improved production efficiency and reduced production costs. In addition, with the improvement of environmental awareness, more and more sheet metal processing companies have begun to adopt environmentally friendly materials and green production processes to achieve sustainable development.

For sheet metal processing companies, continuous innovation and improvement of technological levels are the keys to maintaining competitiveness. With the continuous emergence of new materials and new processes, the sheet metal processing industry is also facing new challenges and opportunities. Only by continuous learning and exploration can we remain invincible in the fierce market competition.

With the deepening development of globalization, the sheet metal processing industry is also facing increasingly fierce international competition. In order to gain a foothold in this highly competitive market, sheet metal processing companies need to continuously improve their competitiveness and innovation capabilities.

On the one hand, companies can improve processing accuracy and efficiency, reduce costs, and improve product quality by introducing advanced production equipment and technology. On the other hand, enterprises can also strengthen exchanges and cooperation with international counterparts, learn from advanced management experience and technological achievements, and promote technological progress and industrial upgrading of the industry.

In addition, companies also need to pay attention to changes in market dynamics and customer needs, and promptly adjust product structure and market strategies to meet the diversified and personalized needs of the market. Only in this way can we maintain our leading position in the fierce market competition.

Sheet metal processing is not only a technology-intensive industry, but also an industry with extremely high requirements for details. During the processing, every link is crucial, and any small error may affect the quality of the final product. Therefore, it is crucial for sheet metal processing companies to have a team with strong skills and rich experience.

These technicians not only need to be proficient in various processing equipment and processes, but also need to have rich practical experience and keen insight. They can accurately understand customer needs, quickly formulate processing plans, and continuously optimize and adjust during the processing to ensure product quality and delivery time.

In addition, with the continuous development of science and technology, the sheet metal processing industry is gradually becoming intelligent and digital. By introducing advanced production management systems and information technology, companies can better monitor and manage the production process and improve production efficiency and product quality.

We produce directly with custom made CNC machining service being our specialization.

Our major products are Bicycle parts, Aluminum switch panel,camera case,scooter rims,optical fiber machine components,etc.

The main machines we have are CNC machining center,CNC lathe machines and normal milling machines,lathe machines,grinding machines and wire cutting machines.

In addition to this, we have completed testing equipment consisting of CMM,Two coodinate measuring machine, height gauge,hardness gauge etc.

Our team includes talented engineering team, technical team, quality management group and sales force.

We have been granted ISO9001 quality management system certification for effective delivery of products and services that meet customers’ expectations both locally and abroad making us a reliable supplier of CNC machining.

High precision, rapid production, customizable designs, suitable for various industries, enhancing production efficiency and quality.

Efficient mass production, precise details, durable and cost-effective, suitable for complex shapes and sizes.

Rapid prototyping, no tooling required, capable of printing complex geometric shapes, wide material selection, endless innovation possibilities.

Precision cutting and forming, high-quality metal parts, customized services, widely used in construction and manufacturing.

We understand that business needs can sometimes be time-sensitive. Our state-of-the-art facilities and streamlined production processes are designed to accommodate urgent orders, allowing us to deliver promptly without compromising on the quality of our services.

Our turnaround time varies depending on the complexity and volume of the order. However, we strive to provide an efficient timeframe while maintaining the highest standards of craftsmanship. Quotes for specific projects will include estimated lead times so that you can plan accordingly.

Consistency is achieved through a combination of advanced machinery, precise engineering protocols, and stringent quality control measures. Each batch undergoes meticulous inspection to meet our strict standards before being released for delivery.

Do you offer any warranties or guarantees on your sheet metal machining services?

We value long-term partnerships and recognize the importance of repeat business. For clients placing bulk or regular orders, we have flexible pricing strategies and may offer discounts or other benefits to foster a mutually beneficial relationship. We invite you to discuss the details during our consultation process.