Understanding CNC Machining Parts: Precision and Innovation

The manufacturing sector has been transformed by CNC (Computer Numerical Control) machining, which offers precision and efficiency that are unparalleled. In various fields, this sophisticated technology is crucial for producing high-quality components. This article highlights the importance, benefits, and applications of CNC machining parts.

What is CNC Machining?

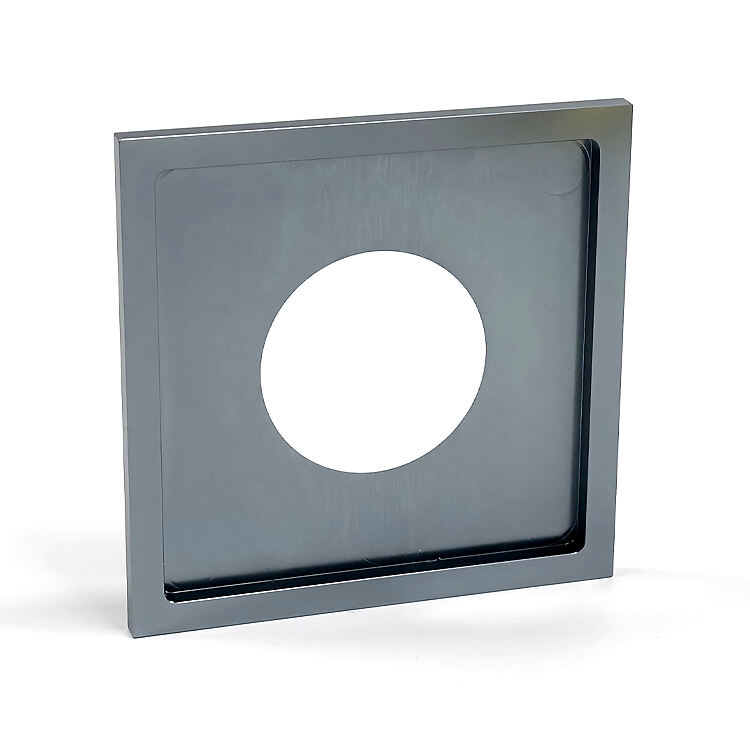

CNC machining is the use of computer-controlled machines to make highly-precise pieces. It involves creating a digital design to direct the machine’s movements resulting in exact cuts and shapes being made. They can perform different procedures like milling, turning of parts and drilling as well as grinding.

Advantages of CNC Machining Parts

Precision and Accuracy: The use of these types of devices guarantees that they will produce items with accurate specifications by comparing them to computers since each part is checked critically with respect to its given requirements thus making any error negligible.

Efficiency and Speed: The time taken for manufacturing through CNC machineries is significantly reduced compared to manual processes that are labour intensive. Automation enables faster production cycles and handling complex designs becomes much easier.

Flexibility and Versatility: These machines work on multiple materials such as metals, plastics or composites among others hence making them applicable in diverse areas like aerospace industry, automotive industry etc.

Cost-Effectiveness: Although purchasing CNC machinery might be expensive at the beginning, there are huge savings realized in the long run due to decreased human labor costs, limited wastage rates regarding raw materials used and increased production speeds which lead to cost effectiveness in general.

Applications of CNC Machining Parts

Aerospace Industry: In aerospace manufacturing environments where turbine blades demand extreme precision along with other engine parts or structural elements tight tolerances must be maintained if safety is not compromised throughout their life cycles.

Automotive Industry: CNC parts are used in the manufacture of automotive engine components, transmission parts and customized fittings. It facilitates quick prototyping and the production of complex geometries that are required in modern vehicles.

Medical Devices: In the medical sector, sophisticated procedures like making delicate instruments for surgery, creating biomedical implants etc., are commonly done using CNC machining. These applications need precision and accuracy.

CNC machining parts play a crucial role in contemporary production owing to their accuracy, efficiency and flexibility.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

BN

BN

LO

LO

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK