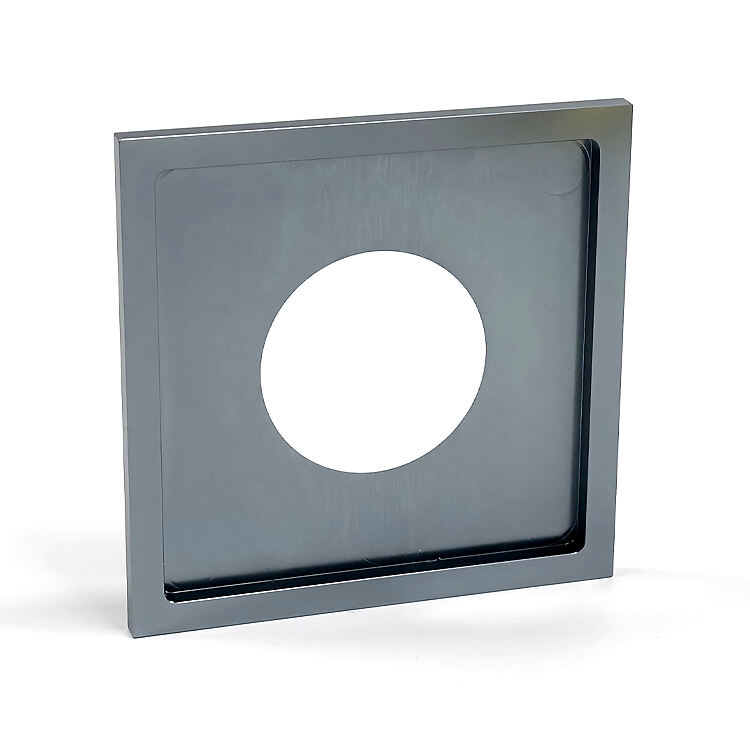

Searching Aluminum Machining Services’ Agility and Accuracy.

The Beginning:

Among the various industries involved in advanced manufacturing, aluminum machining services are significant for creating light-weight and intricate components. It’s a highly demanded material in industries such as aerospace, automotive, electronics, medical equipment etc due to its strength ability to resist corrosion easily and workability. The purpose of this article is to take a deep dive into aluminum machining services by highlighting their versatility, precision capabilities and the overall role they play in modern manufacturing processes.

Knowledge about Aluminum and Its Benefits

Being silvery white metal Aluminum has high strength-to-weight ratio which makes it suitable for applications where weight reduction is vital. The fact that it can be recycled while having natural corrosion resistance makes it highly environmentally friendly. This raw aluminum is used by aluminum machining services to make parts of complex shapes or components using an assortment of accurate methods.

Kinds of Aluminum Machining Services

CNC Machining: Computer Numerical Control (CNC) machining uses sophisticated software and precise tools to carve out extremely precise parts from blocks or billets made of aluminum. Intricate designs are therefore allowed with tight tolerances making it perfect for those components which require very high accuracy.

Milling: With milling metal chips are formed by a rotating cutting tool on the stationary work-piece thus producing desired shapes or contours where needed. It is thin blade process capable of roughing as well as finishing machineries on aluminium pieces.

Turning (Lathe Machining): In turning operation, while the cutting tool moves across the surface of the workpiece made up of aluminum it rotates changing its shape into cylindrical forms or other complex profiles that may arise during this operation . Other symmetrical objects like shafts axles are manufactured through this technique.

Drilling and Tapping: Drilling and tapping operations are essential to creating holes or threads in aluminum parts usually performed alongside other types of metalworking operations which are still known as machining. They ensure fasteners bearings and other components can be conveniently attached during assembly.

Aluminum Machining Precision

Aluminum machined parts offer an incredible level of precision. Modern CNC technology has made it possible to achieve tolerances up to microns, ensuring that the parts fit and function perfectly in their intended applications.

Applications of Aluminum Machined Parts

Aerospace: Aircraft industry predominantly employ aluminum due to its light weight; machined parts such as engine components, airframe structures, landing gear systems etc.

Automotive: In the automotive sector, aluminum machining services are employed to make lighter components that could improve fuel efficiency and overall vehicle performance for instance engine blocks, transmission parts and suspension elements among others.

aluminum machining services embody perfect combination of both accuracy and adaptability in contemporary manufacturing processes.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

BN

BN

LO

LO

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK