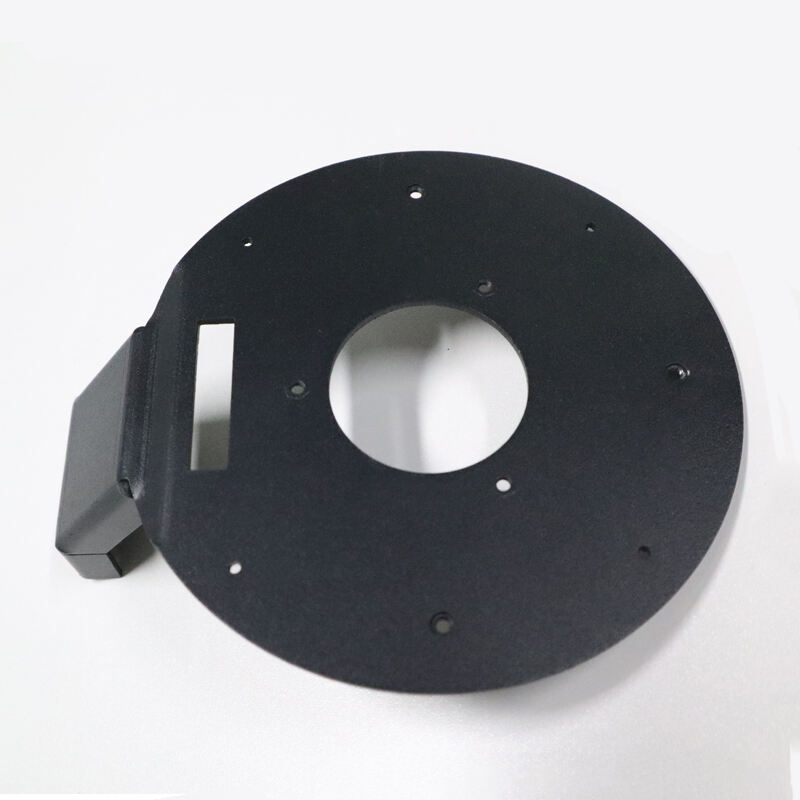

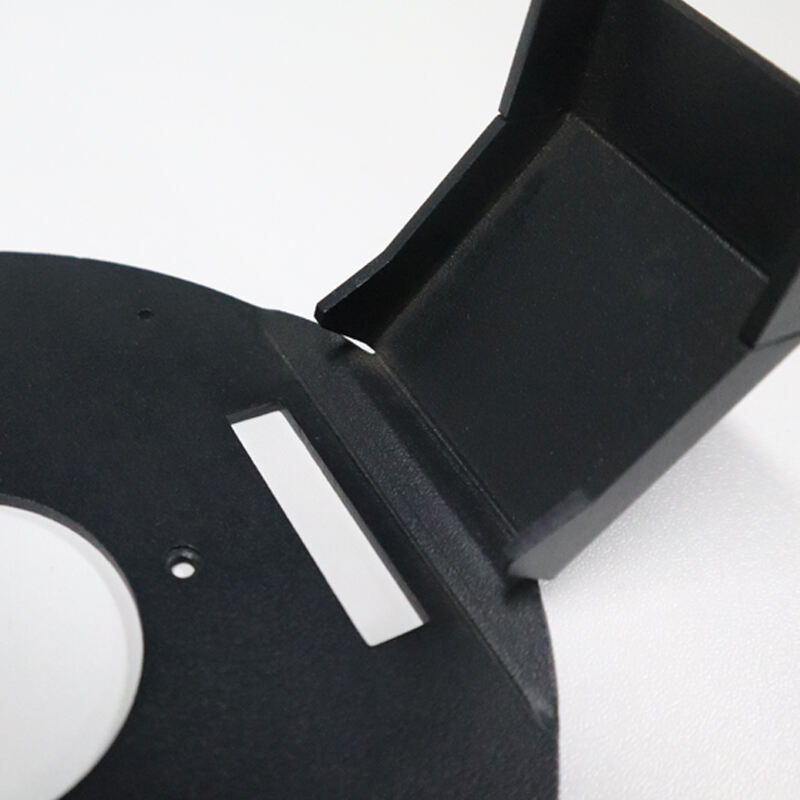

Precision Sheet Metal Working - Customized Solutions

We offer high-quality Precision Sheet Metal Working using advanced laser cutting and CNC stamping technology to ensure the accuracy and durability of each part.

- Overview

- Parameter

- Inquiry

- Related Products

Precision Sheet Metal Working - Customized Solutions

Sheet metal working is a metal processing technology that is mainly used to process sheet metal, including cutting, stamping, bending, welding and other processes. Below are some specific advantages of the sheet metal working process:

Versatility: Sheet metal processing can handle metal sheets of various shapes and sizes to meet the manufacturing needs of different products.

Flexibility: Sheet metal working process can be quickly adapted to design changes and is suitable for small batch production and customized products.

High precision: Modern sheet metal processing technologies, such as laser cutting and CNC bending, can ensure processing accuracy to meet the needs of precision manufacturing.

High Efficiency: Automated sheet metal processing processes can significantly increase production speed and reduce production cycle time.

Cost-effective: Sheet metal processing can reduce material waste and improve material utilization, thus reducing costs.

Ease of Integration: Sheet metal working products are easy to integrate with other components for easy assembly into final products.

Durability: Sheet metal working products usually have very good mechanical properties and durability, suitable for long-term use.

Surface treatment: Sheet metal processed components can be subjected to a variety of surface treatments, such as painting and plating, to improve corrosion resistance, aesthetics or special features.

Design Freedom: Designers can utilize sheet metal processing technology to achieve complex geometries and structural designs.

Wide range of application: Sheet metal processing is suitable for a wide range of metal materials, such as carbon steel, stainless steel, aluminum, copper, etc. Applications include automotive, aerospace, electronics, home appliances, construction and many other industries.

Reduced Subsequent Processing: Due to the high precision of processing, many sheet metal working products require no or very little subsequent processing after production.

Environmentally friendly: Compared to some traditional metal working methods, sheet metal working reduces noise and dust, and has a lower impact on the environment.

These advantages of the sheet metal working process make it an indispensable part of modern manufacturing, and it is particularly suitable for the production of metal parts that require high precision and complex shapes.

Application Scenarios:

Whether for industrial automation, medical devices, electronic equipment or furniture manufacturing, our sheet metal processing products will meet your high standards of precision and durability.

| Place of Origin | Guangdong, China |

| Product Name | Precision Sheet Metal Working - Customized Solutions |

| Material | Steel, Stainless steel, Aluminium, , etc |

| Processing | Laser cutting, CNC punching & bending, Stamping, Welding,etc |

| Finishing | Power coating, Oxidization, Electrophoresis, Galvanization, etc |

| Thickness | 0.2mm-12mm / Customized |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

BN

BN

LO

LO

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK